A solvent trap usually comes up when people talk about firearm cleaning and solvent containment. Basically it catches solvent + debris as it leaves the barrel, so you’re not wiping everything down after.

Some folks want a complete setup and call it good. Others already have parts and only need one piece. Either way, this guide breaks down how solvent trap components fit together (and what matters before you buy).

A solvent trap is used during firearm cleaning to catch solvent and debris as it exits the barrel. Most setups are pretty straightforward: a tube, an adapter that matches your thread pattern, and an end piece to help contain runoff. If you’re new to this stuff, don’t overthink it… focus on fitment and build quality first.

Want the easy route? Kits group matched pieces—tube, thread adapter, and end cap—so everything plays nice together. It’s a solid starting point if you’re not 100% sure what parts you need yet.

Browse complete kits →Already have a setup and just need one part? Super common. Swap a worn cap, change sizes, or grab a different adapter to match your barrel thread. Simple.

If you’re building out a full “be ready” setup, we also carry survival gear and emergency freeze-dried food. And yeah — the close-out products page is worth a quick look too.

This section answers common questions related to firearm cleaning systems, including how they work, what components are involved, and how to choose compatible options.

A solvent trap is a device used during firearm cleaning to capture solvent and debris as it exits the barrel. The system helps contain runoff during routine maintenance and is not designed for sound reduction.

During cleaning, these assemblies reduce mess by collecting solvent runoff and fouling. As a result, many firearm owners use them alongside standard tools such as rods, brushes, and patches.

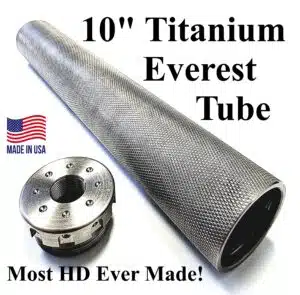

A typical setup includes a tube, a threaded adapter, and an end component. In addition, some designs use sectional or segmented internal parts instead of traditional cup-style layouts, which can simplify disassembly and cleaning. Individual components are available on our parts & adapters page .

Thread compatibility depends on the firearm and barrel configuration. Common examples include 1/2x28 and 5/8x24; however, you should always confirm specifications before selecting an adapter.

These products serve a cleaning and containment role only. They are not designed to reduce sound, and modifying components beyond cleaning use may be subject to regulation.

In general, a complete kit offers a simple starting point with matched components. On the other hand, purchasing individual pieces can make sense when replacing a specific part or configuring a setup around an existing thread option. You can compare available options on our kits page .

The term “solvent trap” commonly describes products used for firearm cleaning and solvent containment. However, federal firearms statutes and regulations do not define this term explicitly.

Instead, the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF) evaluates firearm-related items using statutory definitions found in U.S. law rather than marketing or colloquial terminology. Because of this, classification depends on design features, configuration, and intended use.

Under federal law, a firearm silencer includes not only a complete device intended to diminish the report of a firearm, but also any combination of parts designed or intended for assembling such a device, as well as any individual part intended only for that purpose.

As a result, how a product is designed, marketed, modified, or ultimately used can affect how regulators evaluate it. Lawful configuration and intended application therefore play an important role in compliance considerations.

The products discussed in this guide serve a cleaning and containment purpose. During routine barrel maintenance, they help capture solvent and debris and are not designed for sound reduction.

Modifying components for a purpose outside of firearm cleaning may place the item under additional regulation, including requirements of the National Firearms Act (NFA). Because regulations can vary by jurisdiction and change over time, individuals should remain informed before making any modifications.

Important Notice: This material is provided for general educational purposes only and does not constitute legal advice. Individuals are responsible for understanding and complying with all applicable federal, state, and local laws.

Different solvent trap components are built with different materials and layouts. The table below breaks down the most common options so you can quickly compare what fits your cleaning setup.

| Component | Common Options | What to Know |

|---|---|---|

| Material | Aluminum, Titanium | Aluminum is lightweight and easy to handle. Titanium offers higher strength and corrosion resistance. |

| Tube Diameter | Multiple sizes | Diameter affects internal space and compatibility with certain components. |

| Internal Design | Traditional, Sectional | Sectional designs reduce part count and make disassembly easier after cleaning. |

| End Pieces | End caps, muzzle-style interfaces | Helps retain solvent during cleaning and interfaces with barrel threads. |

| Adapters | Threaded, Quick-connect | Threaded adapters are common; quick-connect styles speed up install and removal. |

Tip: focus on proper fitment first, then choose solvent trap components that match how often you clean and how you prefer to disassemble.